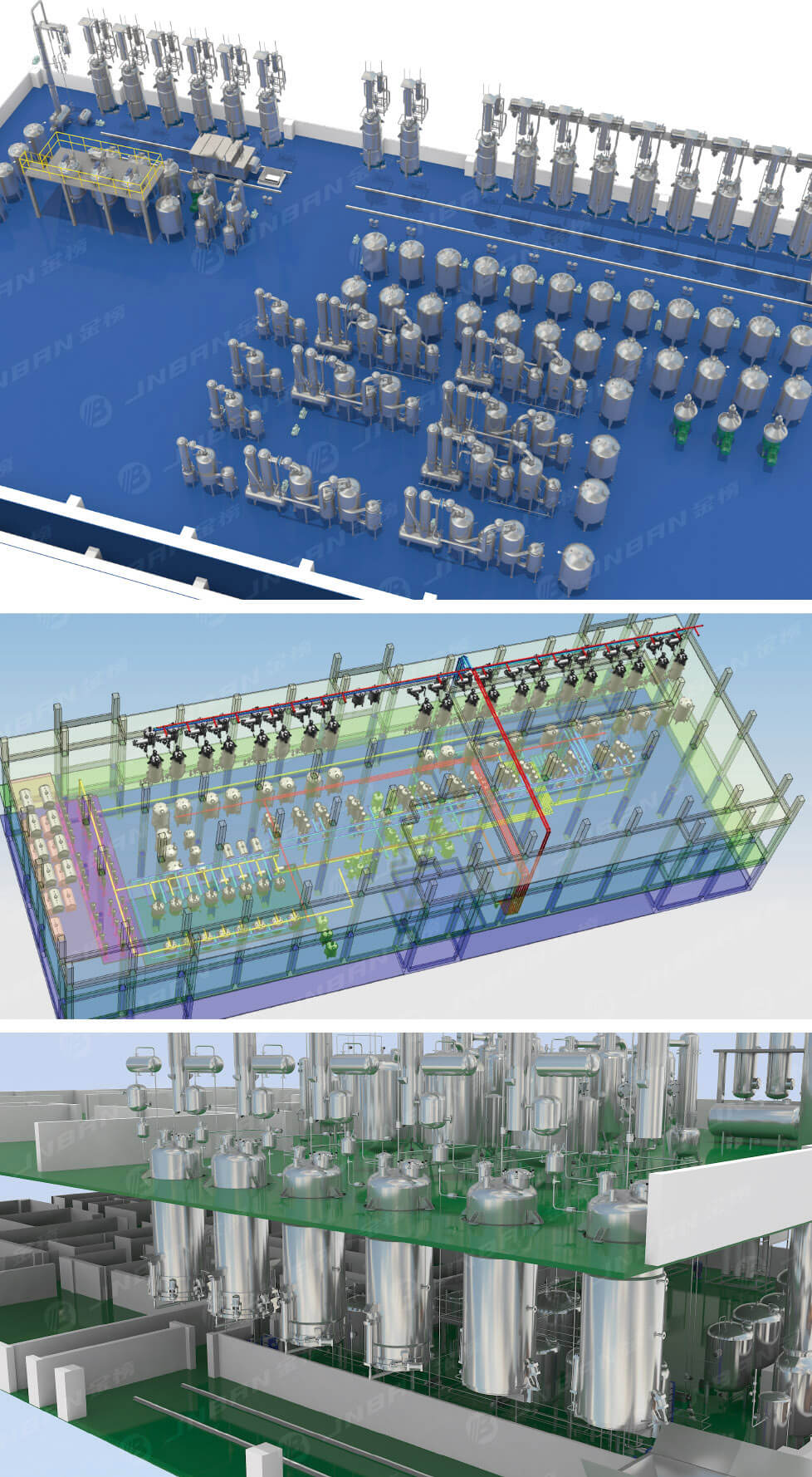

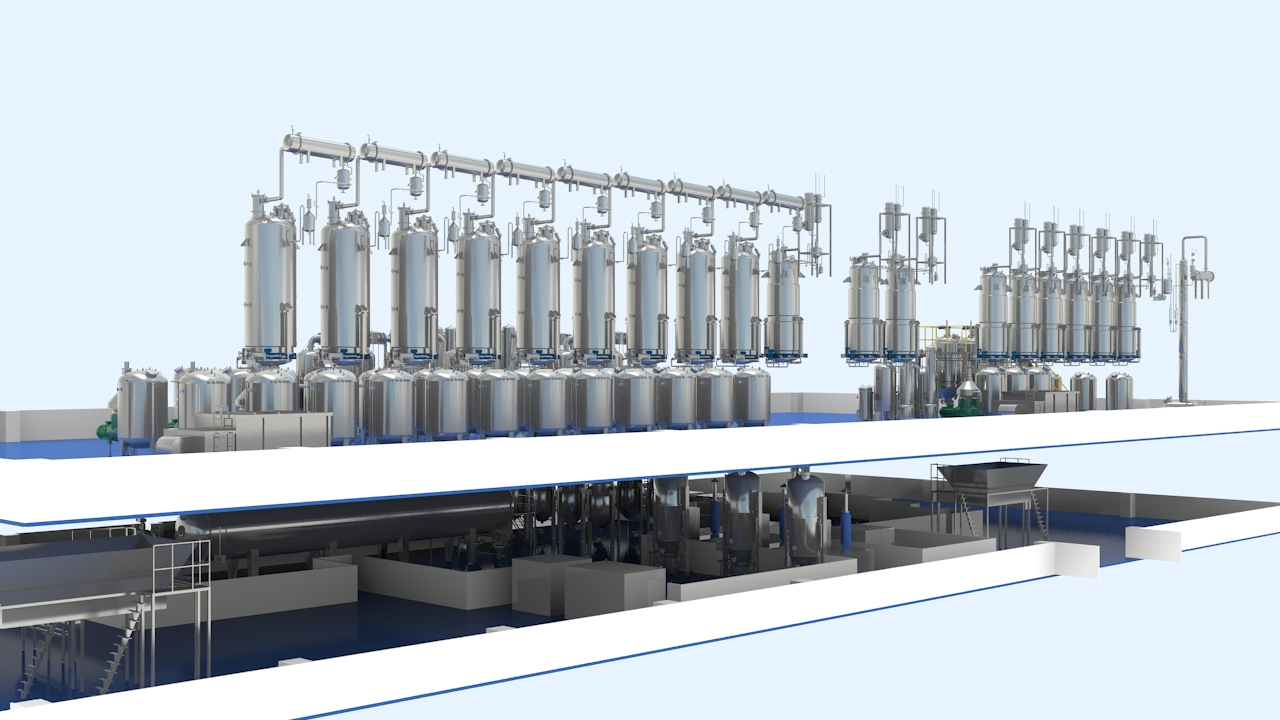

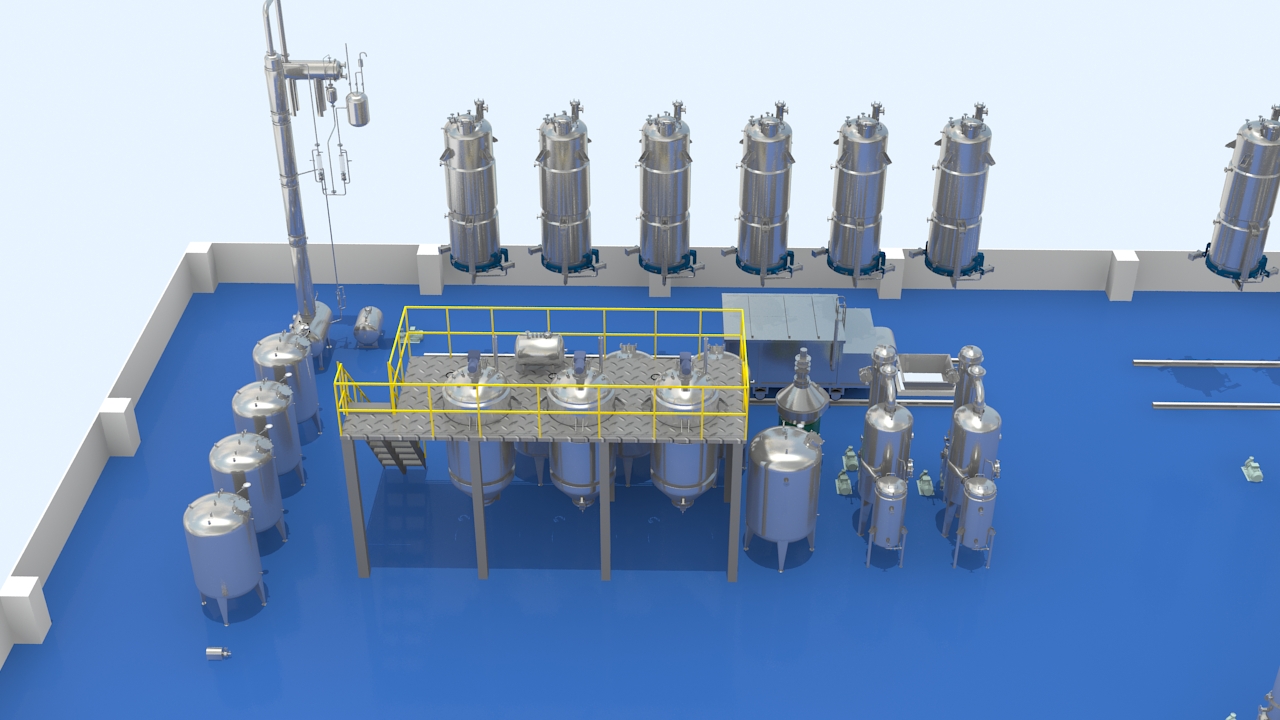

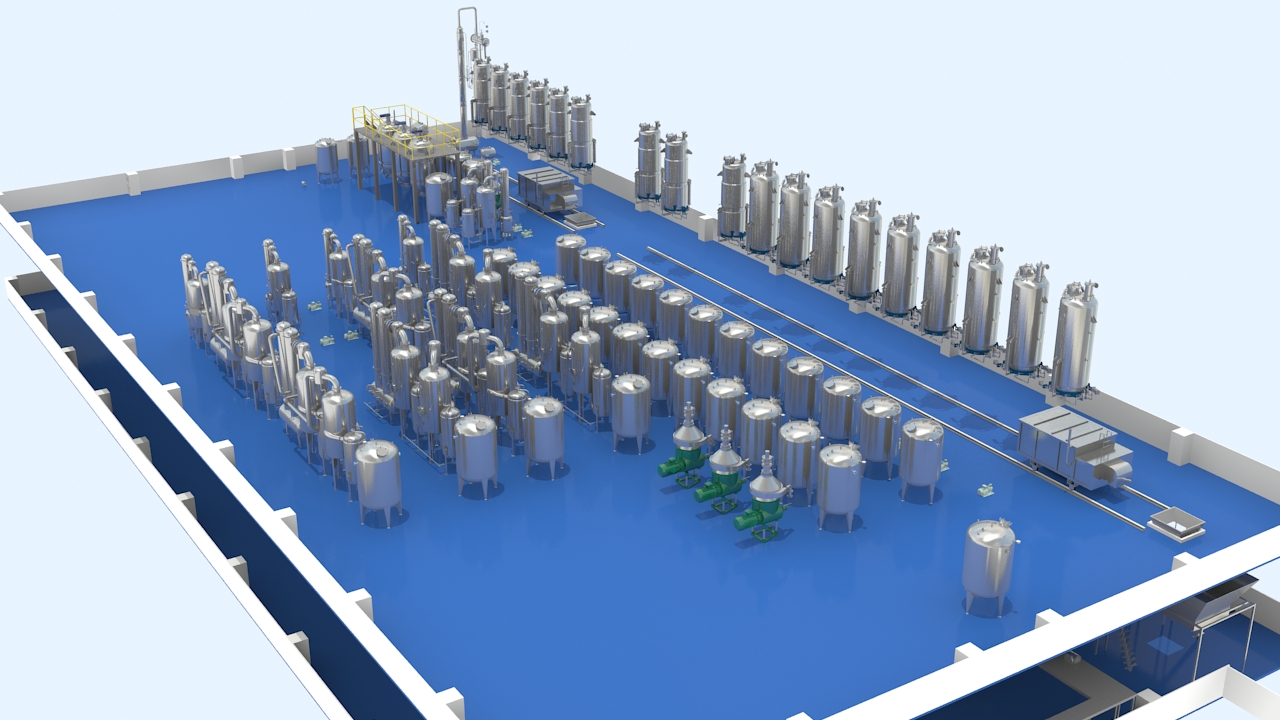

The company can provide customers with engineering, process design, equipment design, engineering installation, complete production line debugging and other ser vices, and provide turnkey projects.

The company can provide customers with engineering, process design, equipment design, engineering installation, complete production

line debugging and other ser vices, and provide turnkey projects.

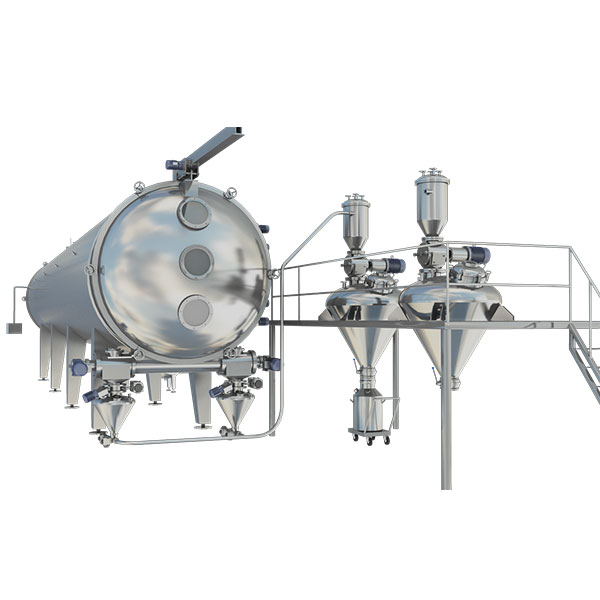

Traditional Chinese medicine hot backset current low temperature draw low temperature concentrate unit comprehensive backset current, ooze and filter drawing, adverse current and hot backset current extraction and concentrate four kinds of principles. abstraction, concentrate two processes go on at the same time, one finish traditional medicine draw, concentrate the new craft of traditional Chinese medicine, take to change the draw pot keep high temperature with atmosphere fry the craft of boiling, utilize vacuum to shoulder proceed low temperature draw and low temperature concentrate, make working temperature to draw pot control in 60-80°C, concentrate temperature control in 50-70°C, guarantee crude drugs effective composition the distillation loss. Meanwhile draw and concentrate produced two steam enter backset current condenser become hot condensation liquid, falling back to and drawing it the pots, add to the crude drugs as the new solvent, the new solvent is passed the crude drugs layer from top to bottom, having played a oozing and filtering dynamically role, the soluble material which dissolves the crude drugs reaches the draw pot bottom, enter the concentrating device to concentrate again. According to practical experience and study for many years, hot condensation liquid of backset current invite within 2.5-3 hours drawing former solvent of pot all change once, can keep a higher density to the draw pot crude drugs in unit time.

The dynamic extraction tank can be used for atmospheric pressure, micro pressure, water decoction, warm imrnersion and cold immersion conditions in herbal&plant, food and chemical industries. The equipment is equipped with a stirring device to make the material extraction sufficient and increase the extraction rate

The produdt s mainly adapted to the concentrated producton processiof traditional herbal&plant health care products. natural seasonings food additves food. chemcal industry and other industries.H can prouide different proportons of extracts with different dryinig production miethods t has advantages of wide application range. easy operanion and low maintenance rate

It is applied to the freeze-precipitation of herbal&plant,oral liquid, food health products, etc, freezing or normal temperature precipitation of suspension,solid-liquid phase separation, and separation of wax and lipid substances.

The rectification column is a tower gas-liquid contact device for rectification. Using the characteristics of different volatility of each component in the mixture, the light component (low boiler) in the liquid phase is transferred to the gas phase, and the heavy component (high boiler) in the gas phase is transferred to the liquid phase, thereby achieving the purpose of separation. The equipment is widely used in solvent recovery in plant extraction, Chinese medicine, food, and chemical industries.

The belt dryer is suitable for continuous drying of raw materials,semi-finished products and finished products such as roots, stems and leaves. It can also be used for continuous drying of aquatic products and other agricultural and sideline products and crops. It is especially suitable for materials with high water content and high heat sensitivity.Successful Project

JNBAN vacuum belt dryers have been included in the“ Eleventh Five-Year National Science and Technology Support Program, Zhejiang Science and Technology Department Major Science and Technology Public Relations Project and Zhejiang Province” Major Science and Technology Special (Priority Theme) Social Development Project. There are 4 papers and 6 patent applications accepted, including 4 invention patents, 2 special authorizations, and 10 practical patents. They won the third prize of Zhejiang Science and Technology Progress Award and the first set of products in Zhejiang Province.……

Wenzhou Jinbang Light Industry Machinery Co., Ltd. is a high-tech enterprise integrating R & D, manufacturing and sales. Professional in the production and sales of pharmaceutical, bioengineering machinery and equipment professional enterprises. The company mainly specializes in consulting, scheme design and manufacturing, budget, on-site installation and after-sale maintenance of traditional Chinese medicine extraction equipment, concentration equipment, separation and purification equipment, alcohol recovery equipment and drying equipment.……

Wenzhou Jinbang Light Ind Machinery Co., Ltd

E-mail: info@jnbantech.com

P.C: 325025

Address: No. 420 Binhai 23rd Road, Binhai Park, Economic & Technological Development Zone, Wenzhou, Zhejiang, China