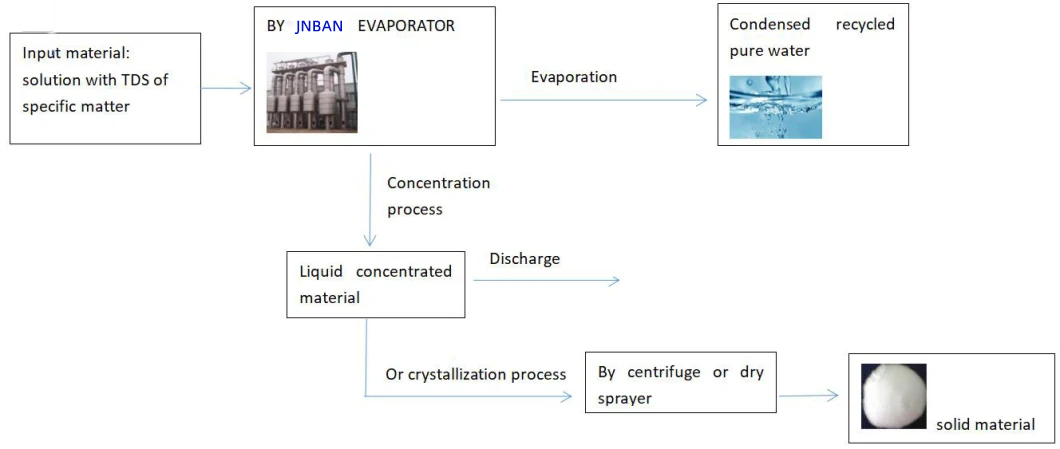

It's applicable for dairy products, beverage,pharmacy, glucose, starch,chemical industry, xylose, citric acid, ammonium sulfate, biological engineering, environmental engineering and waste liquid recovery and treatement. etc.

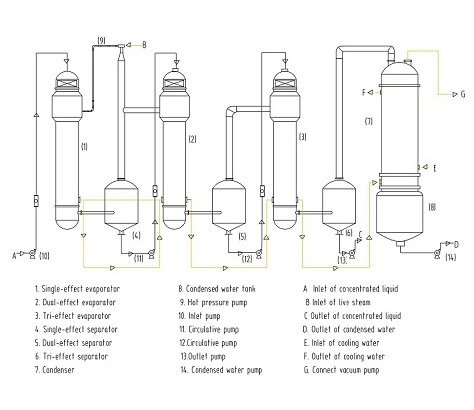

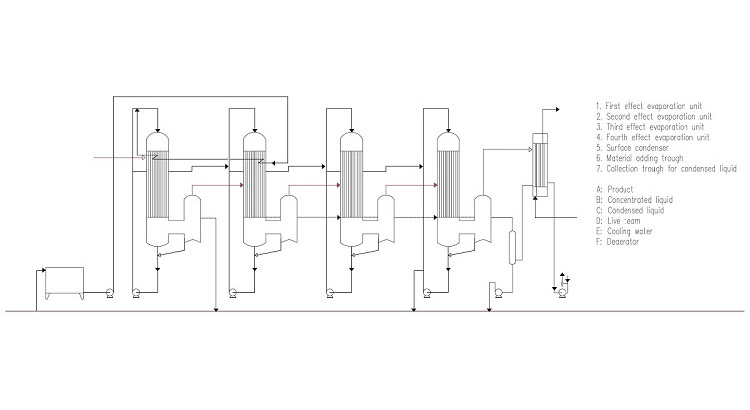

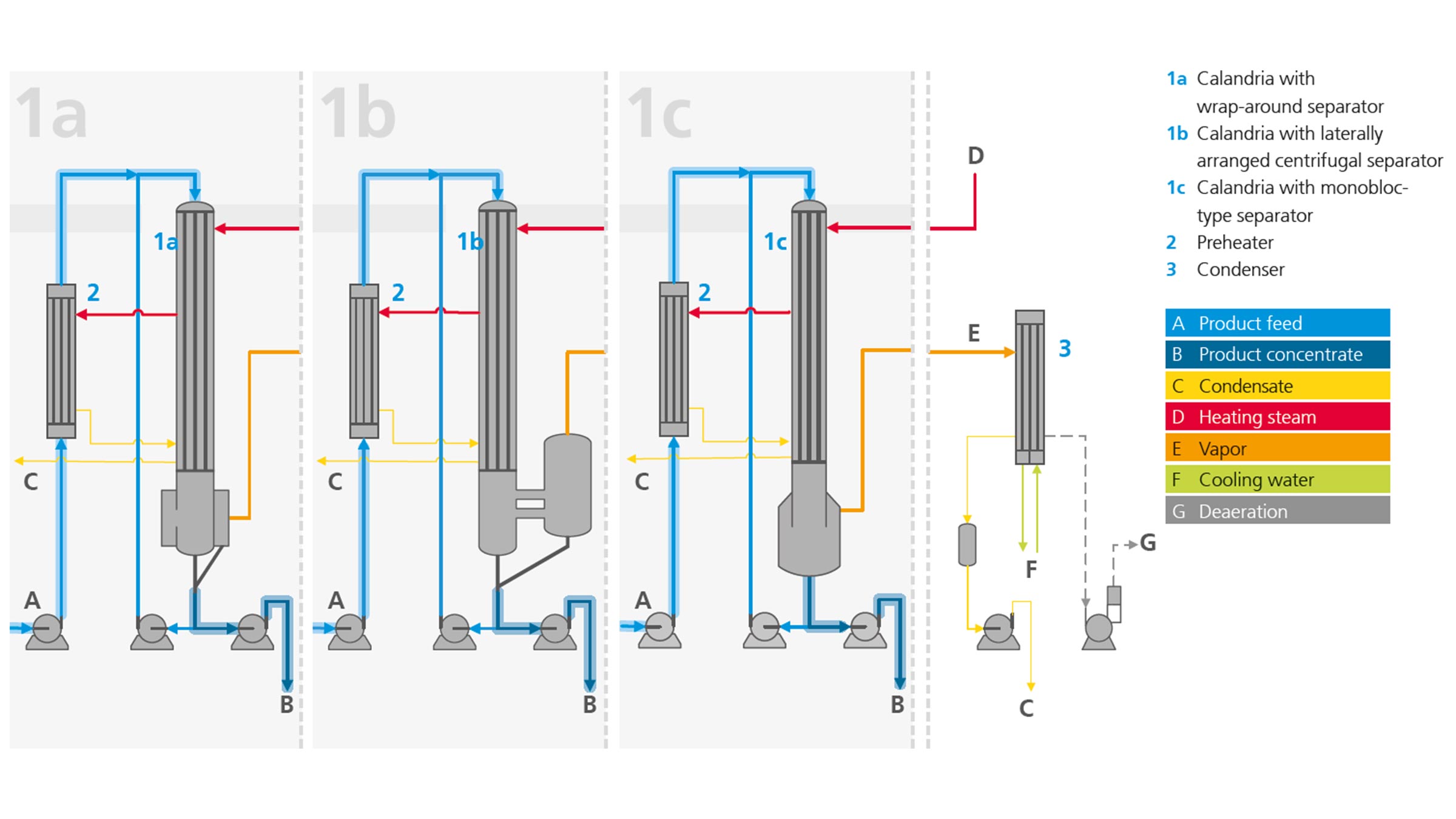

It consists of (first-effect, second-effect, third-effect)separators and evaporators and preheaters,condenser and vaccum pump, feeding pump, circulation pump, discharge pump, condensed water pump and system pipe fittings, etc. Equiped wit CIP spraying cleaning ball, vacuum gauge, thermometer,pressure gauge,and so on.

1.Continuous feeding and discharging, the system is stable and easy to operate. When working in this series of equipment, it only needs to adjust various parameters as required at the initial feeding stage, and at the same time ensure continuous and stable supply of materials, convenient adjustment, continuous and stable concentration and high efficiency, and can recover the solvent at the same time.

2.The concentration ratio is significant (up to 1:5), thermal efficiency is high, and the energy saving effect is remarkable. In the structure of the system, we adopt an optimized design scheme to achieve the evaporation heat transfer coefficient 3400-3800w (m2·K), which is very suitable and advantageous for the concentration of Chinese herbal extracts. The main reason is that the material flows rapidly in the form of a film in the heating tube, and the heating temperature difference is small (only 8-10 ° C), the evaporation temperature is low, and the material can form a rapid flash after entering the evaporator. The residence time and heating time of the chemical liquid in the heating tube are short, and the viscosity of the material is wide (50-500 cp). It is not easy to crystallize and coke out due to heat, and the damage to the active ingredient is small, the heat energy is utilized sufficiently, and the energy saving effect is remarkable.

3.Easy to use advanced control methods. Because the LJN series concentrating process mainly uses the temperature of each effect as the control parameter, the parameters of the system are stable during operation, and it is easy to adopt advanced automatic control (PLC and human-machine interface control), and the control equipment cost is relatively low, for the production of traditional Chinese medicine. Achieve greater automatic control with greater convenience.

4.The structure design is advanced and reasonable. In terms of structure, we adopt an optimized design scheme. I use advanced liquid distribution device to distribute the liquid in the pipe during the feeding, so that the material can enter the heating pipes evenly. At the same time, the inner wall mirror with high quality imported is selected. The tube is used as a heating tube, so that the flow resistance of the material in the tube is small, the speed is fast, and the scale is not easily precipitated. In order to improve the yield of concentration, the system is equipped with an advanced mist trap to eliminate the ability of entrainment of the mist, the separation efficiency can reach 96-99%, and the resistance drop is small.

5.Low steam consumption: 1kg steam can evaporte 3.5kg water.

6.Low evaporation temperature:part of secondary steam can be inhaled into single-effect heater through spray type hot pressure pump, this would make full use of the heat and the evaporation temperature is low.

| Vacuum degree(MPa) | Evaporation temperature(℃ ) | |

| Single effect | 0.048-0.057 | 80-85 |

| Dual effect | 0.031-0.038 | 70-75 |

| Three effect | 0.019-0.025 | 60-65 |

| Specification / Model | UN500 | UN1000 | UN1500 | UN2000 | UN3000 | UN5000 | UN6000 | UN8000 |

| Evaporation | 500 | 1000 | 1500 | 2000 | 3000 | 5000 | 6000 | 8000 |

| Steam pressure(Mpa) | 0.1-0.25 | 0.1-0.25 | 0.1-0.25 | 0.1-0.25 | 0.1-0.25 | 0.1-0.25 | 0.1-0.25 | 0.1-0.25 |

| Steam consumption(kg/h) | 185 | 370 | 555 | 740 | 1110 | 1850 | 2220 | 2960 |

| Circulating water consumption(T/h) | 5 | 10 | 13 | 15 | 18 | 25 | 30 | 40 |

| Medium | ||||||||

| Dimensions(mm) Lx W x H | 7080x900x3500 | 7680x1000x4000 | 8380x1100x4600 | 8890x1100x4600 | 9500x1300x4900 | 10200x1400x5300 | 10800x1500x5800 | 11500x1600x5800 |

| No | Item | Specifications |

| 1 | Feed Liquid | Sodium chloride |

| 2 | Water Evaporation Flow | 800 kg/h |

| 3 | Feed 20-25% | 1000 kg/h |

| 4 | Discharge 55% | 520 kg/h(Crystal 200kg/h) |

| 5 | Working Vapor Pressure | 0.3-0.5Mpa |

| 6 | Working Vapor Consumption | 330 kg/h |

| 7 | Cooling water volume | 37 T/H (Inlet water: 32ºC, Outlet water:38ºC) |

| 8 | Total Power | 50.4 KW (Cooling water pump is not included) |

| 9 | Total Weight | 12Tons |

| 10 | Material | Touch face TA2,other 316, pump2205 |

| L | Dimensions | 7000×3000×8500MM |

JNBAN vacuum belt dryers have been included in the“ Eleventh Five-Year National Science and Technology Support Program, Zhejiang Science and Technology Department Major Science and Technology Public Relations Project and Zhejiang Province” Major Science and Technology Special (Priority Theme) Social Development Project. There are 4 papers and 6 patent applications accepted, including 4 invention patents, 2 special authorizations, and 10 practical patents. They won the third prize of Zhejiang Science and Technology Progress Award and the first set of products in Zhejiang Province.……

Wenzhou Jinbang Light Industry Machinery Co., Ltd. is a high-tech enterprise integrating R & D, manufacturing and sales. Professional in the production and sales of pharmaceutical, bioengineering machinery and equipment professional enterprises. The company mainly specializes in consulting, scheme design and manufacturing, budget, on-site installation and after-sale maintenance of traditional Chinese medicine extraction equipment, concentration equipment, separation and purification equipment, alcohol recovery equipment and drying equipment.……

Wenzhou Jinbang Light Ind Machinery Co., Ltd

E-mail: info@jnbantech.com

P.C: 325025

Address: No. 420 Binhai 23rd Road, Binhai Park, Economic & Technological Development Zone, Wenzhou, Zhejiang, China