We have been focused on the research, development and production of extraction tank used in the industrial since 1997.

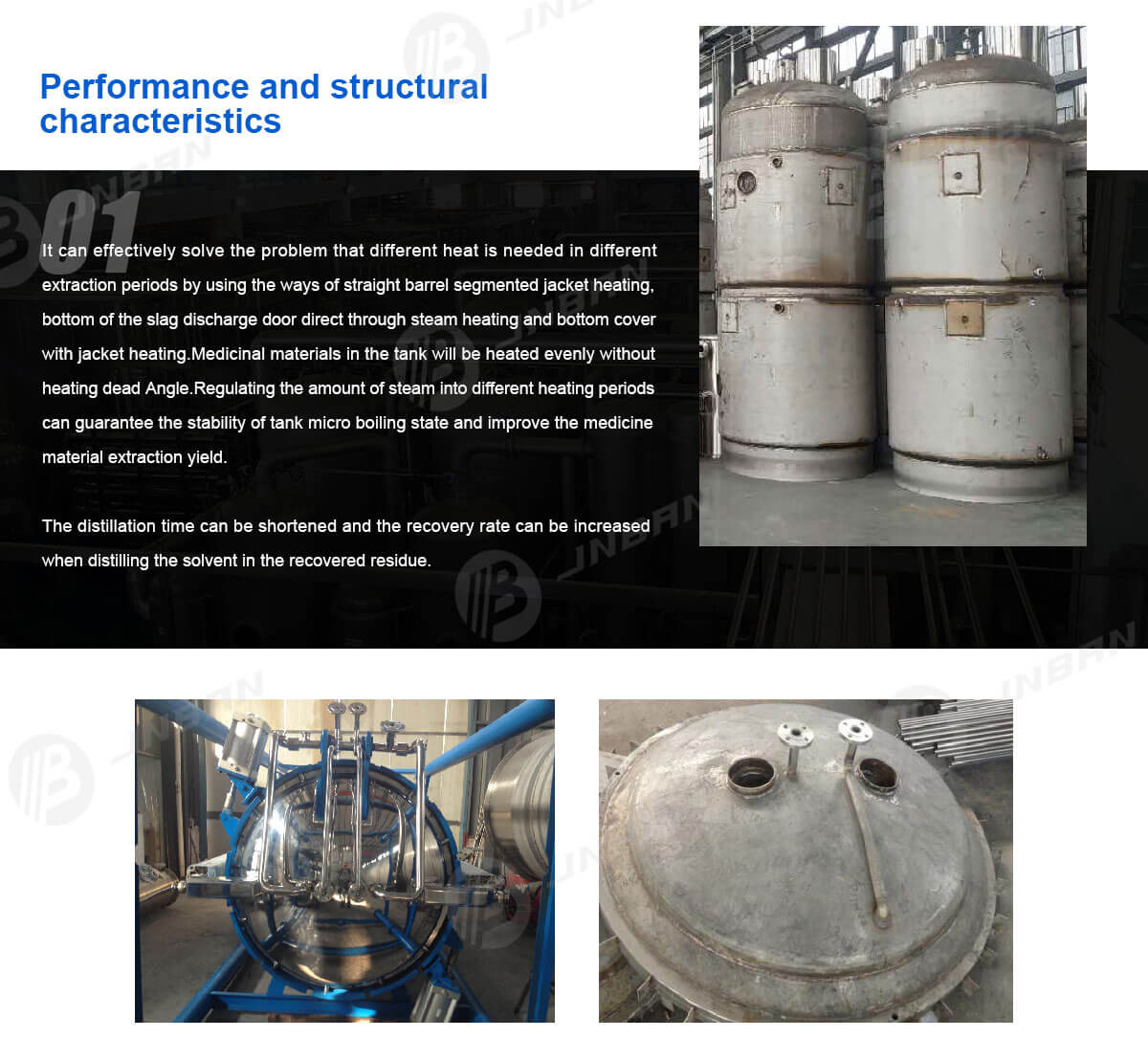

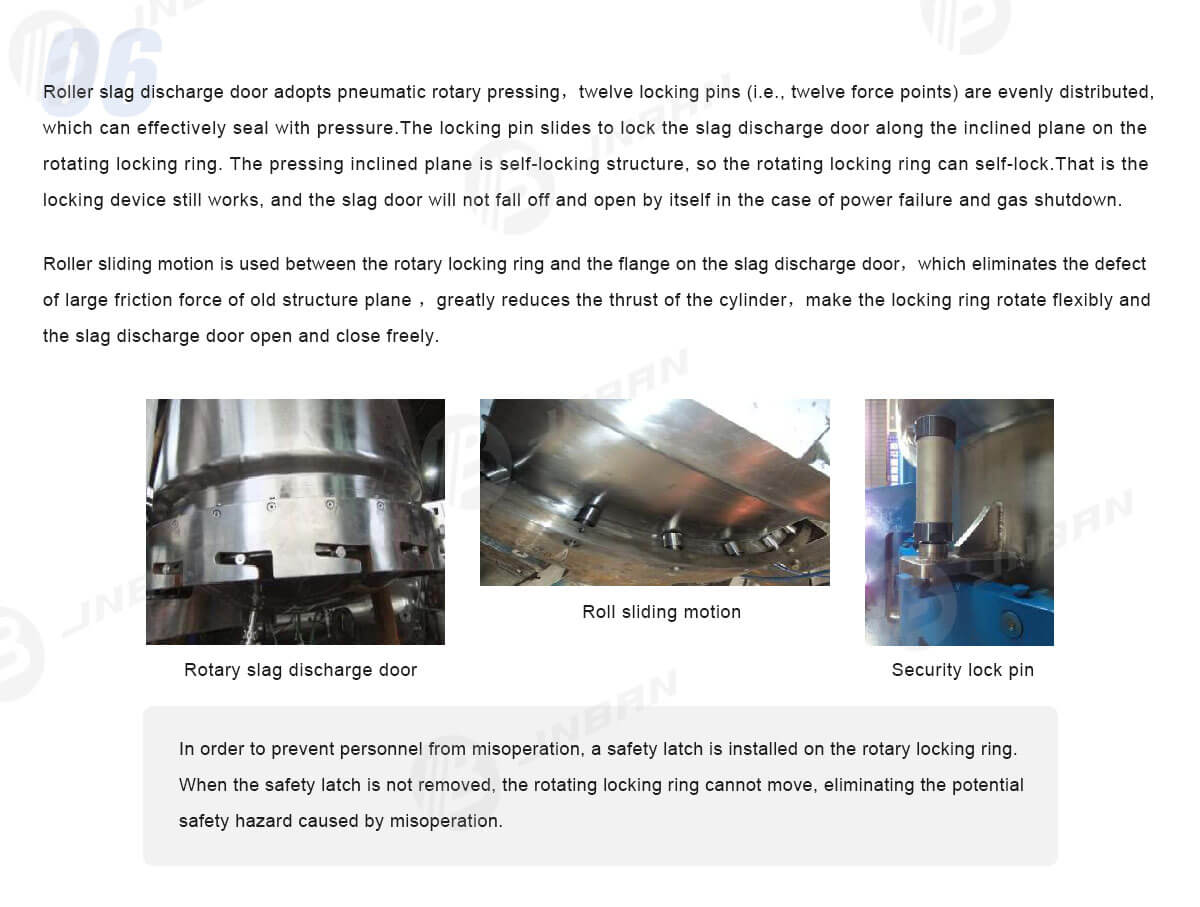

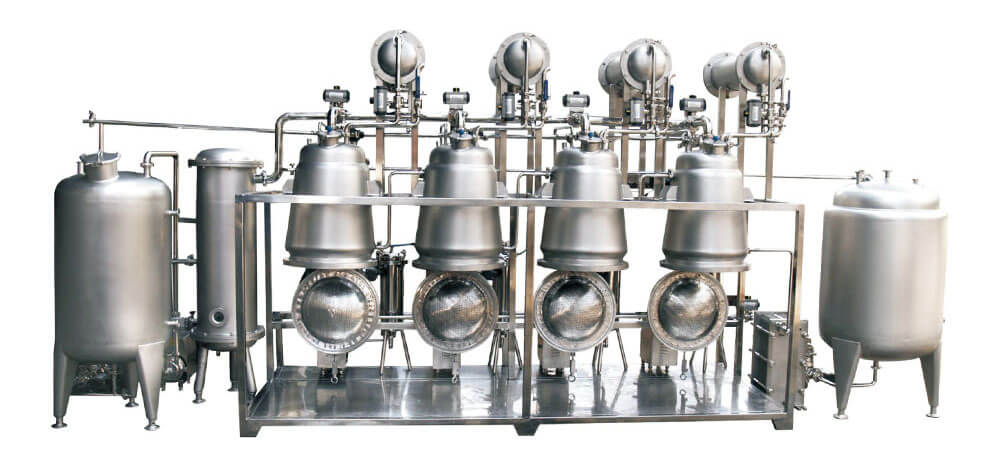

Combined with the characteristics of German E&E extraction tank, we redesigned and developed a new generation of extraction tank,which has a great improvement in the heating, filtration, slag discharge, and slag discharge door seal. It got the user's affirmation through years of practice.

Equipment performance optimization, good operability, energy saving and environmental protection, overall beautiful.

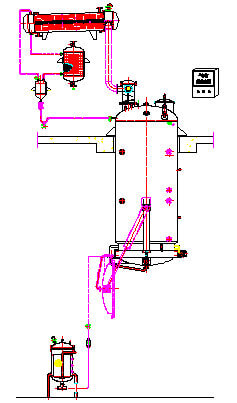

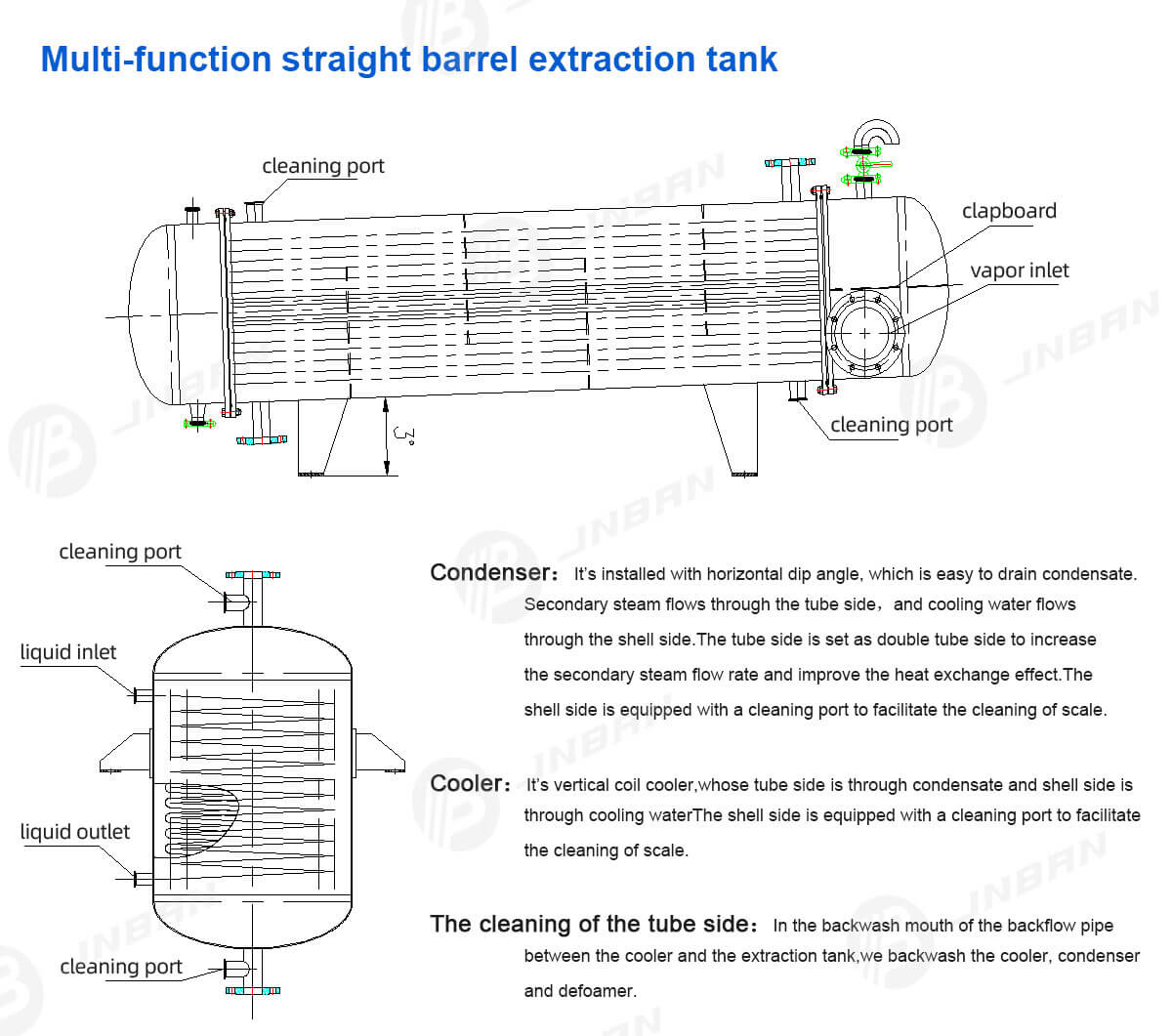

Component:The equipment is made up with tank, defoamer,condenser, cooler, oil-water separator, oil receiver, duplex strainer, pump and pipeline.

AccessoriesThe tank is equipped with CIP cleaning automatic rotating spray ball, temperature gauge, pressure gauge, explosion-proof sight glass lamp, sight glass, quickopening feeding port, etc., to ensure easy operation and meet GMP standards. The inner cylinder of the equipment is made of 304 and 316L.

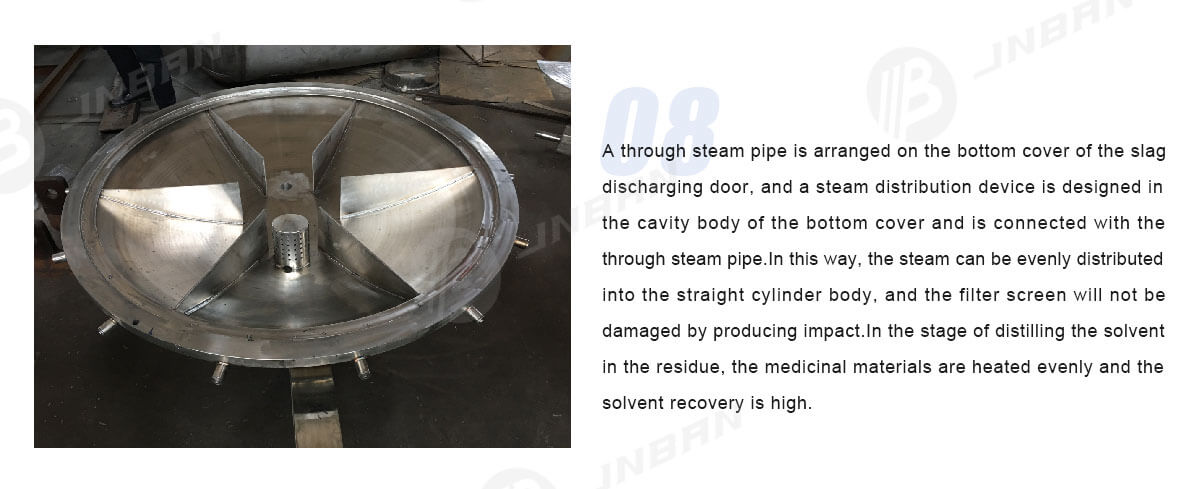

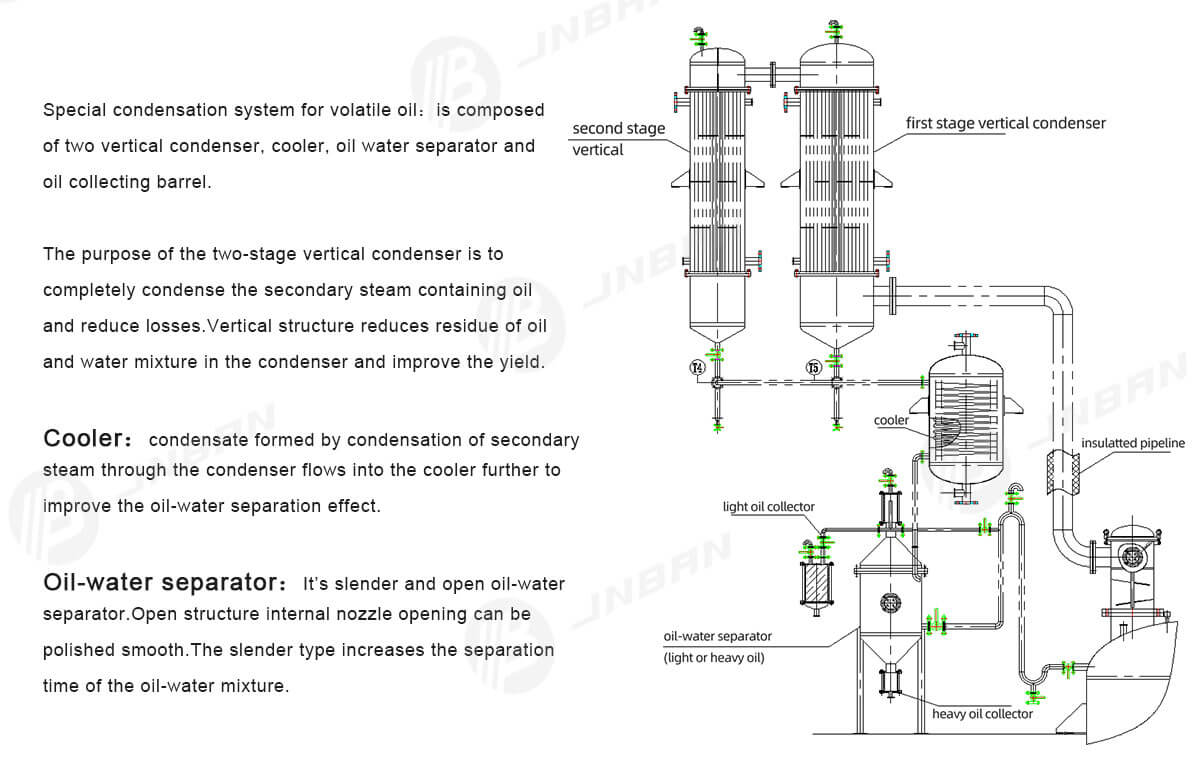

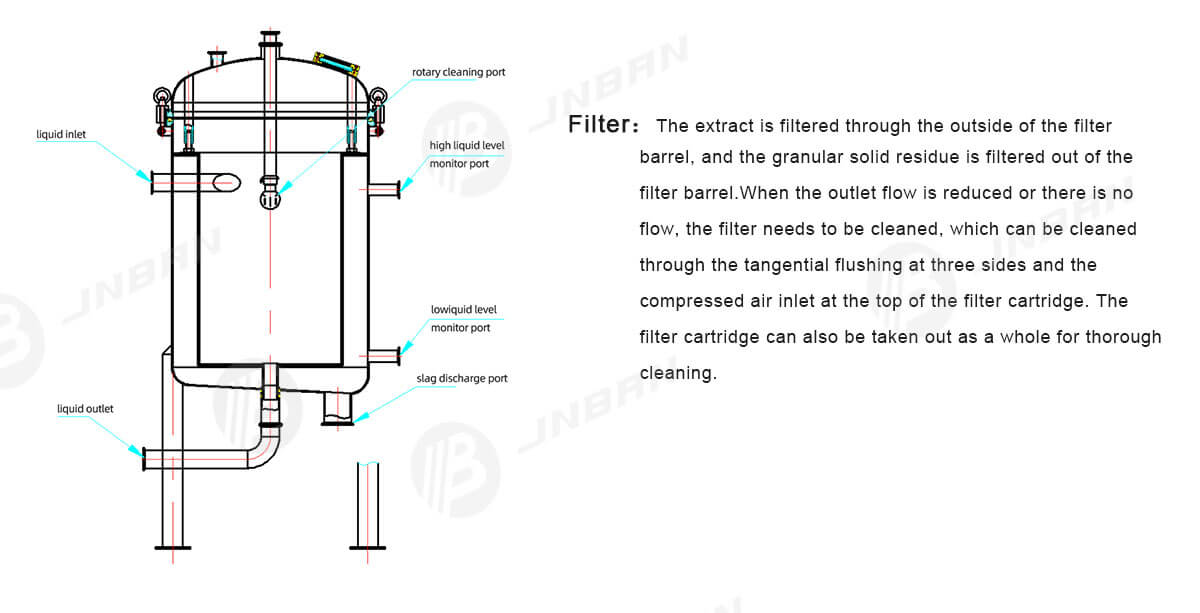

Solvent is added into the extraction tank. After soaking,solvent will be heated through steam in the jacket. Medicine liquid will boil in the tank. According to different boiling points of solvent,low boiling point components start to first boil into secondary steam, then through condensation, cooling to oil and water separate. Reflux or discharge can be determined according to process conditions. The oil-water separator uses the different density of oil and water to carry on the upper and lower layers, so as to obtain the volatile oil. In addition, due to a difference in the concentration of medicine liquid in the upper, middle and lower parts of the main tank in the heating process, it can make medicine liquid from the bottom of the main tank through the filter and pump back to the upper part of the main tank for circulation, to achieve dynamic extraction.

This is a machine that extracts essential oils and active ingredients from various materials like leaves, flowers, barks, etc.

It also extracts natural products, herbs, recycles volatile aromatic oils, and concentrating extracts.

Besides, it can extract and concentrate these substances at the same time.

There are many areas you can use this machine for extraction purposes.

Some common uses include:

This machine has several benefits and will assist in your herb extraction process. Indeed, you require a high-quality extraction machine that will assist you to achieve the best processes.

Here, we shall look at some reasons why you should buy a herb extraction machine:

This is without a doubt the most beneficial reason for you to buy a herb extraction machine. Besides, there are various types of this machine for you to choose from meaning you need to be keen when purchasing.

However, the quality of the herb extracts will depend on the quality and grade of the raw product.

The type of work area you have determines the herb extraction machine that you can operate. The advantage is that these machines are available for both small-scale and large-scale production.

Small-scale laboratory research may opt for a table-top herb extraction machine. Also, we have large ones that process large capacities of extracts per unit time.

No matter what your budget is, you will find a herb extraction machine that is within your budget range. The prices will vary depending on the manufacturer.

A herb extraction machine will operate fast and effectively. Imagine operating a machine that can process between 5 and 200 liters in a few hours.

This allows you to meet your customer needs within a short period.

These machines will save you a lot of money in the long run. This is especially true for the fully automatic versions since they work independently.

Despite being expensive to purchase, they require minimal supervision during operation. This saves you in recurring costs such as the cost of labor.

Herb extraction machines are easy and simple to operate. Besides, you can operate the machines just after simple training.

However, some will need more drills before you can operate them easily. Fully automatic herb extraction machines are the simplest to operate.

This is because once you enter the processing parameters, the machine will handle all the tasks independently.

This means the method of operation and its suitability. Also, you can use different kinds of solvents such as alcohol, water, etc.

Besides, you can choose between non-solvent-based and solvent-based operational machines.

This will cover the machine in case it gets faulty or has a system failure after you purchase it. The warranty period varies depending on the type of machine and the manufacturer.

Besides, the manufacturer guarantees you free repairs and servicing if the machine breaks down within the warranty period.

Also, check the specifications and terms and conditions of the warranty as they vary from one manufacturer to another.

These machines will not break easily meaning you will use them for long periods. This is evident when you properly maintain and clean the machine from time to time.

Besides, they do not need frequent technical servicing.

These machines always comply to set international standards for health and safety reasons. Besides, it allows you to operate the machine without instances of danger and produce quality herb extracts.

Some of these standards are the American Society of Mechanical Engineers [ASME], cGMP, RoHS, CE, among others.

The herb extraction machine has both extraction and concentration capabilities. This makes it easy for you to extract substances and maintain the right concentration for usage.

Also, it saves you money as you have two systems in one machine.

The machine makes use of high-quality SU304 stainless steel. This means the entire process is hygienic and there will be no contamination to the products as the material is resistant to corrosion.

Besides, stainless steel is easy to clean and maintain.

The machine makes use of temperature control systems. This will ensure you achieve accurate temperatures throughout the extraction process.

Besides, they also have a jacket heating mechanism which makes sure you achieve even heating on the products.

The herb extraction machine has vacuum pumps that make use of a noise reduction mechanism. This means the entire herb extraction process is quiet.

Also, it will prevent hearing damage to you and lowers noise pollution.

It is possible to use a herb extraction machine for processes such as:

The various industries that make use of this machine include:

These include:

Here, you will place the entire or relatively powdered crude herb in a container that has a solvent. Then you place a stopper on the container and allow the mixture to remain at room temperature.

Allow this to stand for a minimum of 3 days while frequently agitating the mixture till it all dissolves together. Thereafter, strain the mixture and press the marc [damp solid substance].

After the mixture stands for a while, you will clarify it by filtration or decantation.

Here, you will boil a specific amount of crude herb in water for a specific duration. After this, you will cool and strain or filter the solution.

Besides, decoction is suitable when you are extracting constituents that are water-soluble and heat-stable. Also, you will use decoction methods when you are preparing extracts of Ayurvedic.

They are also known as “quath” or “kawath”. In this process, the beginning ratio of the crude herb and water is known, for instance, 1:16 or 1:4.

Thereafter, this volume comes down to one-fourth the original or starting volume through boiling in the extraction process. After this, you will filter and use the concentrated product as it is or process it further.

This is a common procedure that you will use for the extraction of active ingredients when preparing fluid extracts and tinctures. A percolator is a narrow vessel that has the shape of a cone on both ends.

First, you will moisten the solid ingredients in menstruum then allow it to stand for an average of 4 hours. Also, make sure you properly seal the container then pack the mass and close the top part of the percolator.

Besides, you will also add some extra menstruum which will form shallow layers above the mass. Then, you will allow the mixture to macerate for 24 hours in the enclosed percolator.

After this time, you will open the exit of the percolator then allow the liquid inside to drain slowly.

Also, you can continue adding menstruum. This is to ensure the percolate measures three-quarters the amount of final product you require.

Thereafter, you will press the marc and add the liquid to the percolate. Also, add sufficient amounts of menstruum to produce the suitable volume.

Then you will use filtration or a standing process, then decant the liquid mixture.

In this process, you will prepare fresh infusions through the maceration of crude herbs for a short time. Also, you will use boiling or even cold water in this process.

They are dilute solutions of the constituents of crude herbs that are readily soluble.

This is also a method of maceration where you will apply a gentle amount of heat during the extraction process.

Also, you will use the digestion method when a slight increase in temperature is not objectionable. By doing this, the efficiency of the solvent menstruum will increase.

Here, you will add a fine powder of the crude herb in a porous bag or a thimble. The thimble composes of a strong filter paper.

Then you will heat the extracting solvent then condense the vapor. The vapor that condenses then drips inside the thimble that has the crude herb thereby extracting it through contact.

Once the liquid level rises above the siphon tubes, it moves into the flask. The process continues until no residue forms on the siphon tubes when evaporating.

This method has an advantage over other methods because you can extract large amounts with a small quantity of solvent.

Small-scale industries use it for batch processes only. However, large-scale industries can use it as it is economical when you convert it to a continuous extraction process.

This method entails soaking the crude herbs for some time. During this process, it will ferment and generate alcohol in situ which facilitates the extraction of active ingredients.

The alcohol that forms will serve as a preservative. In instances you are planning the fermentation on earthen vessels, make sure it is not new.

Also, boil water in the vessel before using it. Large industries use metal vessels, wooden vats, or porcelain vats in place of earthen vessels.

Here, you will produce fine slurry by pulverizing wet raw materials in toothed disc disintegrators. Also, the product moves in one direction inside the cylindrical extractor as it comes into contact with the solvent.

The extract will have more concentration the more distant the starting substance moves. When you optimize the flow rate of the material and the amount of solvent, you will achieve complete extraction.

Besides, the method is efficient and takes less time while posing no danger when the temperatures are high. Extract in high concentration will exit via one end of the extractor and the marc exits from the other exit.

The agenda of this method is to lower the use of organic solvents and increase the sample throughput. Important factors to consider include pressure, modifiers, temperature, restrictors, sample volume, and analyte collection.

Some of the other methods include:

These solvents include:

These include:

The solvent should be immiscible with the solution you want to extract. Also, the more polar an organic solvent is, the more it is soluble with water.

Organic solvents that have low polarity are suitable as organic extracting solvents.

The ingredients you are extracting should be soluble with the extracting solvent. Also, impurities from, I.e. a reaction, should not dissolve in the extraction solvent.

Make sure the extraction solvent is sufficiently volatile. This makes it possible for you to remove it from the extract through distillation.

These solvents come in varying price ranges. For instance, water is cheap whereas ether and glycerine are costly.

It is suitable when the solvent you are using is non-toxic and is not flammable. However, only a few solvents meet both criteria.

Non-toxic but flammable solvents include ether and hexane. Toxic but flammable solvents include chloroform and dichloromethane.

A solvent that is both toxic and flammable is benzene.

These include:

These are common machines as they are reliable, flexible, and have a high capacity.

They can handle disperse systems that are hard to handle such as those possessing high interfacial tension.

Besides, they cope with liquids that are highly viscous and solid-liquid slurry.

Here, a pump will create short amplitude pulses that overlap the normal liquid phase flow. The column may have packing or plates with perforations.

It has the advantage of low axial mixing and a low increase in axial mixing that increases within the column diameter. Pulsation causes the liquid to move in the heavy phase during the upward stroke.

Also, the heavy phase jets into the light phase during the downward stroke.

Light liquid enters via the bottom part and changes to tiny droplets when it reaches the nozzle distributor. The light droplets rise as the heavy mass moves downwards.

Application of centrifugal force lowers residence time and accelerates phase separation. They are suitable in applications where contact time should be short, for instance, chemically unstable systems.

They have two phases that flow in a countercurrent pattern.

They assist in improving new droplet formation while increasing interfacial turbulence which causes high efficiency. The two classes here are the rotary-agitated and vibrating-plate column.

These include:

Yes, we have multifunctional herb extractors. These machines have both extraction and concentration systems.

This depends on the specification of the machine. A machine with a specification of 20 L or less will share a single tank to conduct both extraction and concentration.

Those that have a specification of 50 L or more have separate extraction and concentration tanks.

These include:

This part acts as a heat transfer material to cool the extract and solvent.

This part will separate water and oil mixtures into separate components.

This part allows you to observe the flow direction, condition of the flow, and the average flow rate.

This component will ensure you achieve accurate temperature during the entire extraction process.

It provides heat to the materials thereby enhancing the extraction and concentration process.

This part will automatically release the materials when the pressure or temperature is above the set limits. It thereby prevents damage to the machine.

Here is where you will input all the extraction parameters and monitor the entire extraction process.

It is a star-shaped impeller that rotates eccentrically within a casing that has liquid. The vanes dip in the liquid at varying depths as it revolves thereby forming gas-filled cavities between the liquid and the vanes.

This part is suitable for pumping gas as gas-filled cavities increase and decrease during its revolution.

The stages involve the following:

Here, you will introduce the solvent from the operating tank to the extraction tank. It then flows to the herb material via a safety hose and extracts the ingredients from the plant.

The time and pressure this process takes depend on the solvent you are using. The soaking duration is the time the solvent is in contact with the plant substance.

The herb extract will collect at this part of the machine. Pressure in the system will automatically push the solution via a silkscreen.

It then moves to the separator then collects in the collection vessel.

Here, a water jacket will evenly apply heat to the solution and the solvent begins to evaporate. As it vaporizes, the pressure builds and forces it out of this system via a valve leaving behind the extract.

The evaporating solvent flows via safety pipes and settles at the bottom of the vessel. A recovery pump will withdraw the solvent from the sieve system through a connector. Also, you can apply heat to hasten this process.

This part assists in cleaning the vapor from the expansion filter as it moves to the recovery pump.

Pulses will drain the solvent in here and the fumes settle. Then you will discharge it and channel it to the operating tank for recycling.

The primary features of typical Herb Extraction machine include:

The heat can come from various sources such as:

This is by constructing the machine with high-quality stainless steel that is easy to clean and resistant to corrosion.

Yes, this is to ensure the machine complies with proper designs, operates efficiently, and promotes proper monitoring. GMP compliance leads to the construction of high-quality and reliable machines.

Depending on the type of machine, the price may range between 600 USD and 750,000 USD.

However, the price range will depend on the herb extraction features and capability.

This is because ethanol is an explosive and flammable solvent.

The final product can come out as:

Yes, we do offer training on how you should install the machine. Also, we offer training on how you will operate the machine.

These machines come in various specification capacities such as:

The suitable capacity of the tank for laboratory herb extraction machines is 20L. This is because the sample volume for the experiments you are conducting is small.

Before we ship you the herb extraction machine, we perform granulation tests. The tests involve extracting Chinese medicine and other food ingredients on every granulator.

Besides, we shall repeat the same test three times using the same processes. Once we finish the repeat tests, we will operate the machine for 72 hours.

This run time happens without the processing of any materials.

After all this, the person responsible for the test will impend a signature and approve the shipping.

At Pilotech we have a range of plant extraction equipment such as cannabis oil extraction machine, and coffee extraction machine, alongside other solvent extraction equipment.

Contact us now for all your herb extraction equipment needs.

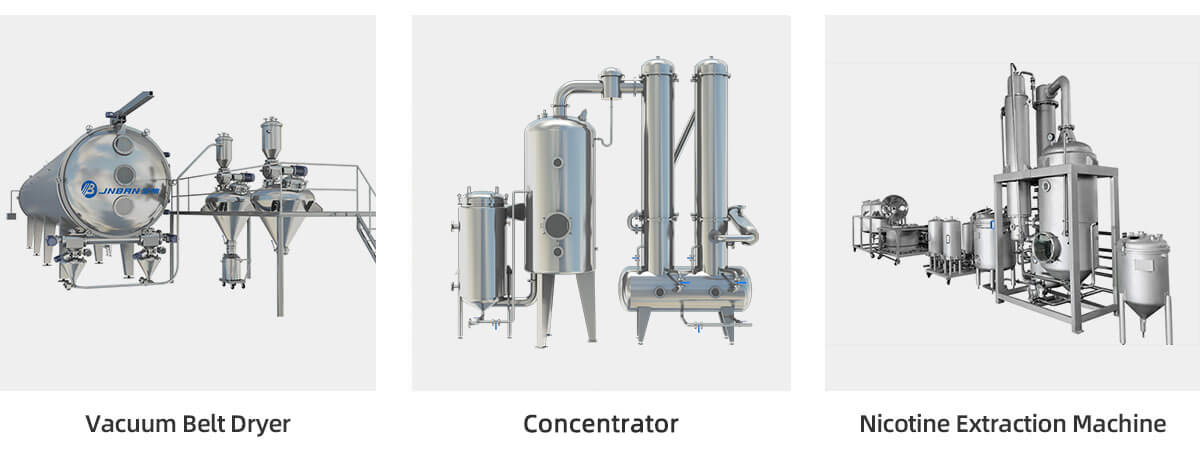

JNBAN vacuum belt dryers have been included in the“ Eleventh Five-Year National Science and Technology Support Program, Zhejiang Science and Technology Department Major Science and Technology Public Relations Project and Zhejiang Province” Major Science and Technology Special (Priority Theme) Social Development Project. There are 4 papers and 6 patent applications accepted, including 4 invention patents, 2 special authorizations, and 10 practical patents. They won the third prize of Zhejiang Science and Technology Progress Award and the first set of products in Zhejiang Province.……

Wenzhou Jinbang Light Industry Machinery Co., Ltd. is a high-tech enterprise integrating R & D, manufacturing and sales. Professional in the production and sales of pharmaceutical, bioengineering machinery and equipment professional enterprises. The company mainly specializes in consulting, scheme design and manufacturing, budget, on-site installation and after-sale maintenance of traditional Chinese medicine extraction equipment, concentration equipment, separation and purification equipment, alcohol recovery equipment and drying equipment.……

Wenzhou Jinbang Light Ind Machinery Co., Ltd

E-mail: info@jnbantech.com

P.C: 325025

Address: No. 420 Binhai 23rd Road, Binhai Park, Economic & Technological Development Zone, Wenzhou, Zhejiang, China