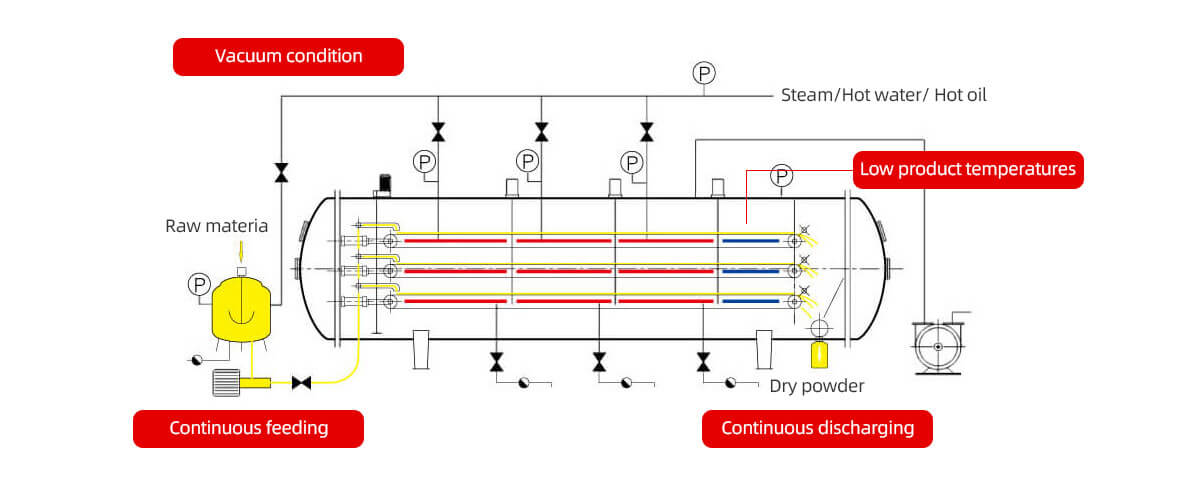

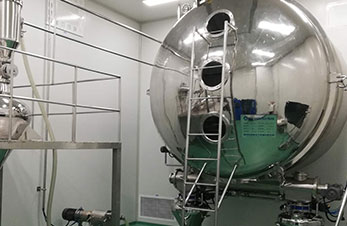

JNBAN Belt Vacuum Drying (BVD) is a method of continuously distributing liquid raw materials on a conveyor belt under vacuum conditions.The materials are dried with the conveyor belt on the heating plate, and then cooled, embrittled and pulverized. A low temperature drying method. During the whole drying process, the extract is in a vacuum, closed environment, and the drying process is mild(operating temperature 30-135° C), which can maintain its physical properties to...

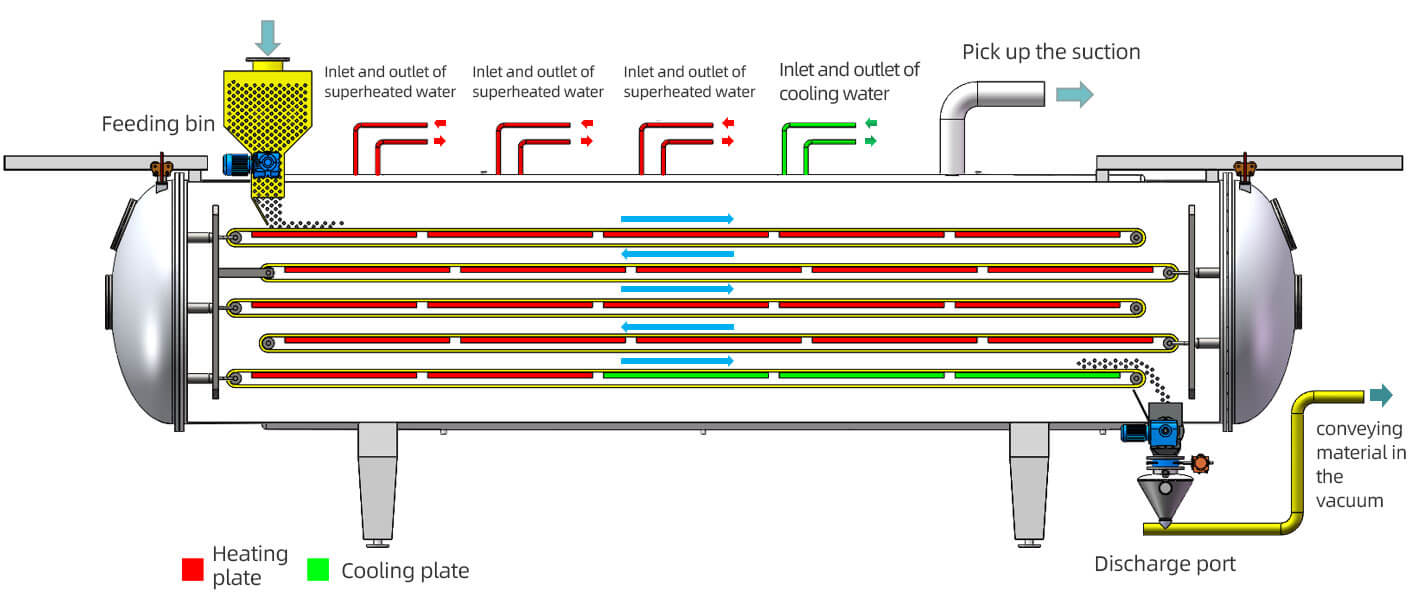

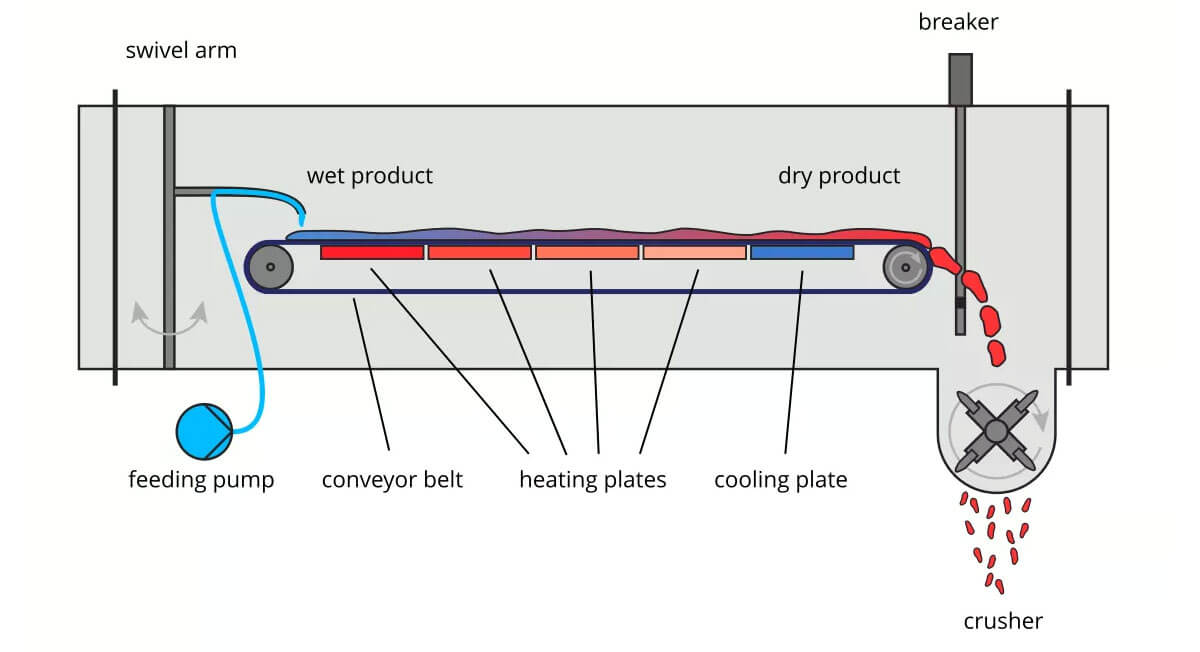

Belt Vacuum Dryer is a method of continuously distributing liquid raw materials on a conveyor belt under vacuum conditions. The materials are dried with the conveyor belt on the heating plate, and then cooled, embrittled and pulverized. A low temperature drying method. During the whole drying process, the extract is in a vacuum, closed environment, and the drying process is mild (operating temperature 30-135° C), which can maintain its physical properties to the maximum extent and obtain a high quality final product.

Since the material is gradually dried under a vacuum for a period of time, the particles obtained by drying have a certain degree of crystallization effect, and at the same time, there are micropores inside from the microscopic structure. After directly pulverizing to the required particle size, the flowability of the particles is very good, and it can be directly tableted or filled with mash, and the particles have good fast solubility.

In addition, a series of parameters can be adjusted online to meet the process requirements of different products, such as the belt speed of the vacuum (solid) belt drying track, the thickness of the layer, the drying temperature, the vacuum degree and etc. The dry product can retain its color, aroma and taste to the utmost extent, and obtain a high quality final product.

Vacuum belt drying technology has a wide range of applications and can be applied to most extracts and solid. Especially for materials with high viscosity, easy to build, thermoplastic and heat sensitive, vacuum belt drying can overcome the shortcomings of too dry and too dense spray drying powder. In addition, a series of parameters such as drying time of vacuum belt drying, feed rate, material thickness, drying temperature and environmental vacuum can be adjusted to suit the process requirements of different products, for heat sensitivity, high concentration, high sugar content, Materials such as high viscosity are also fully tested. At this point, belt vacuum dryers are far superior to spray dryers.

BVD series vacuum belt drying unit is a modern pharmaceutical equipment that Wenzhou Jinbang Light Industry Machinery Co., Ltd. has successfully developed in recent years.

The only equipment manufacturer in China that has obtained 2 invention patents in the field of vacuum belt dryers.

China's first manufacturer to independently develop vacuum belt dryer equipment that meets FDA standards.

It has been put into large-scale production in the first line of many well-known pharmaceutical, food and biological enterprises in China. The operation quality of equipment is stable, and the effect of energy saving and emission reduction is obvious.

The BVD series vacuum belt dryer was evaluated by the expert group organized by the Science and Technology Department of Zhejiang Province, and passed the design and manufacture of the scientific and technological achievements of Zhejiang Province in 2008 (identification certificate number: Zhejiang Technical Association Identification [2008] No. 186). Technology is at the international advanced level.

BVD series vacuum belt dryers have been included in the“ Eleventh Five-Year National Science and Technology Support Program, Zhejiang Science and Technology Department Major Science and Technology Public Relations Project and Zhejiang Province” Major Science and Technology Special (Priority Theme) Social Development Project. There are 4 papers and 6 patent applications accepted, including 4 invention patents, 2 special authorizations, and 10 practical patents. They won the third prize of Zhejiang Science and Technology Progress Award and the first set of products in Zhejiang Province.

1. Using digital integrated manufacturing technology, automatic detection and control during dynamic vacuum drying is realized.

2. Adopting digital axial automatic rectification technology to overcome the problem of deviation of the belt during vacuum drying. The belt conveyor system has an automatic online correction function to ensure continuous operation of the equipment for a long time.

3. Adopting new superheated water heating technology, it can be adjusted freely online in the temperature range of (30-135℃ ). Due to the liquid closed-loop heating method, no discharge and no loss, the heating temperature stability and equipment Energy consumption and utilization are superior to traditional steam heating technology.

4. The vacuum degree adopts fully automatic on-line adjustment and control technology, which can optimize the combination of main process parameters such as drying temperature, vacuum degree, feed rate and drying time, so that the working utilization rate of the equipment can reach the most ideal economic benefit.

5. CIP automatic online cleaning system, diversified cleaning methods, can carry out all-round cleaning without any dead angle, the cleaning effect is thorough and fast, in line with GMP requirements.

6. The batching system, the feeding and discharging system can carry out a variety of optimized design, configuration and combination according to different material characteristics, which have met the user’s process requirements.

7. Based on the principle of humanized design: the main body adopts thermal insulation measures to keep the working temperature of the equipment and the operating environment temperature within a suitable range. The inside and outside of the equipment are designed with corresponding detection channels to facilitate daily maintenance.

At present, most of the lithium hydroxide drying is the use of disc dryer in China. Although the disc dryer has short process flow, simple operation and wide application, there are still many problems.

Applied to the drying of lithium hydroxide, the vacuum low-temperature belt-type solid continuous dryer has unique advantages, which can completely solve the product quality problems caused by the traditional disc dryer.

In short, the quality indicators of the vacuum belt drying product are obviously better, the most important thing is the consistency and stability, while the disc drying, the product quality fluctuates, does not have this stability.

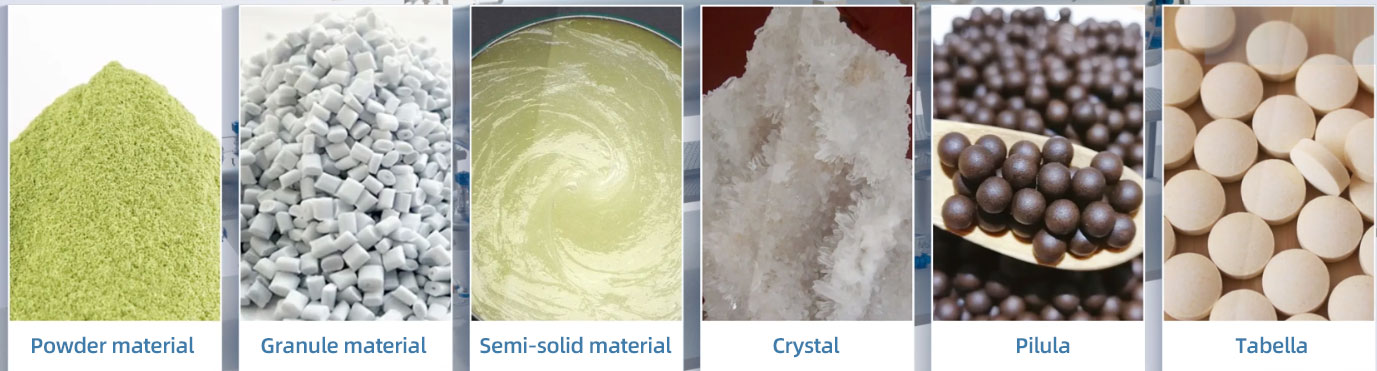

Vacuum Belt Dryer for powder and particle

| Model | Exch Heat area | Drying temperature | Feed moisture content | Dry material moisture content | Heating medium | Water |

| JBG3-15 | 15 m² | 20-135° C (Adjustable) | 10-80% (Mobility) | 0.3-5% (Adjustable) | Superheated water | 8-12Kg/h |

| JBG5-35 | 35 m² | 18-25Kg/h | ||||

| JBG5-50 | 50 m² | 25-35Kg/h | ||||

| JBG5-70 | 70 m² | 35-45Kg/h | ||||

| JBG5-80 | 80 m² | 40-60Kg/h | ||||

| JBG7-120 | 120 m² | 70-90Kg/h | ||||

| JBG9-160 | 160 m² | 90-120Kg/h | ||||

| JBG11-220 | 220 m² | 120-150Kg/h |

Note: The above evaporation is calculated according to the evaporation water. If the organic solvent is evaporated, the evaporation capacity will be greatly improved. The height of the equipment depends on the installation method. The above equipment is highly available for reference!

● The drying process is automatic,continuous and pipelined

● None secondary moisture absorption,waste,pollution

● Stable continuous feeding and discharging

● The temperature of drying process is 30-200 degrees celsius(precision adjustable)

● The operating cost is one third of that of traditional drying and its labor cost is low

● The product recovery rate is over 99%

● Drying time is adjustable from 20 minutes to 200 minutes

● Automatic PLC control

● Automatic online CIP cleaning

● The solvent content of the finished product is controllable

● The solvent recovery rate is over 99%

Belt vacuum dryer working principle

Lithium hexafluorophosphate, lithium difluorosulfonimide(LiFSI), lithium fluoride (industrial grade/battery grade),lithium oxide (single/anhydrous), lithium carbonate and other lithium salts,cobalt salts such as cobalt sulfate, cobalt chloride, gallium salts such as nickel sulfate,ternary precursor, electrolyte additive, etc

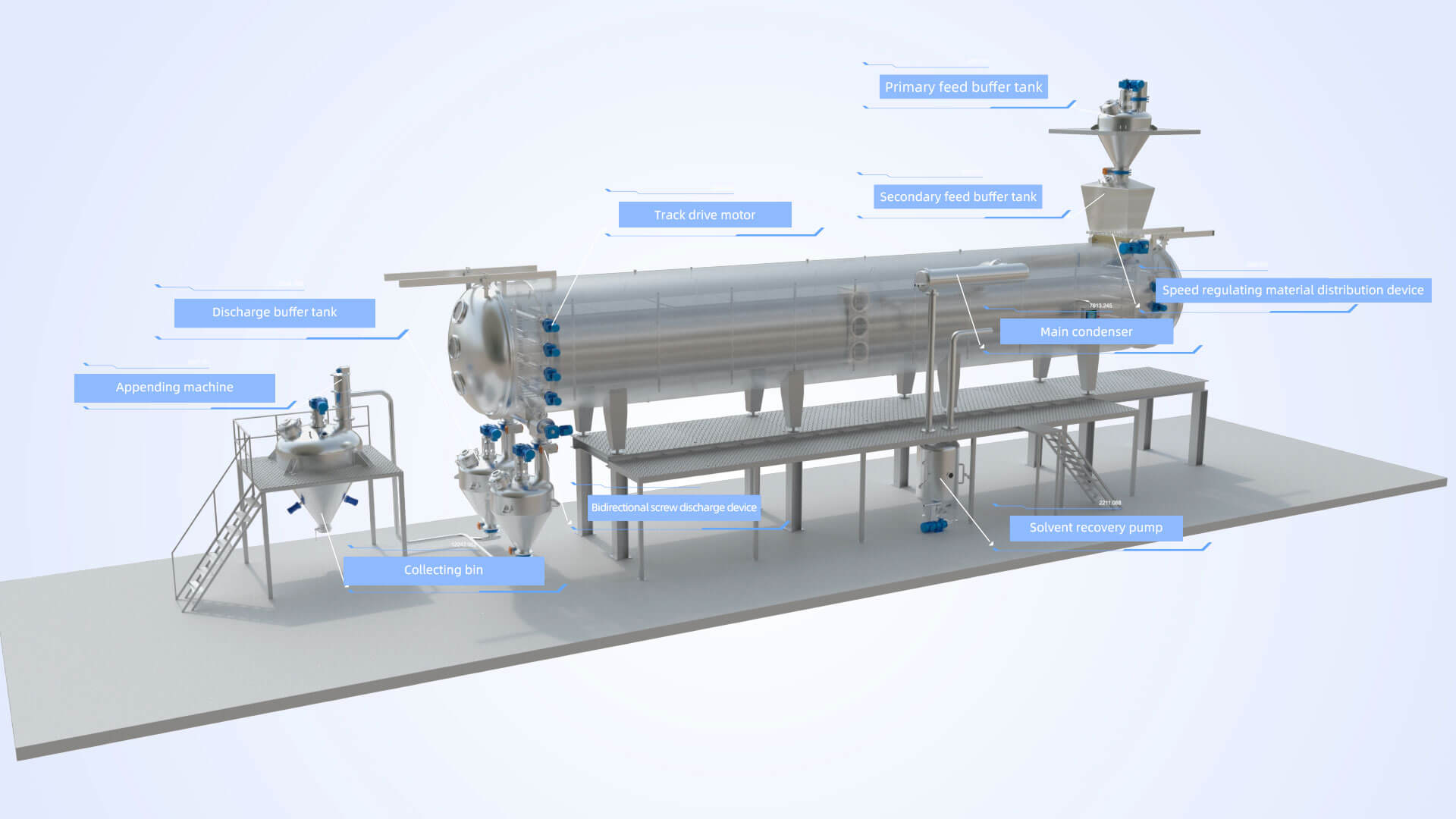

JNBAN Feed System

JNBAN Heating System

JNBAN Vacuuming System

JNBAN CIP Cleaning System

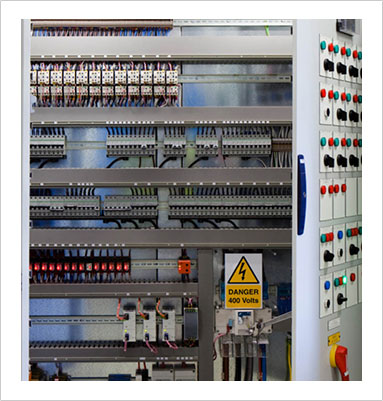

JNBAN Control System

JNBAN Control Cabinet

Project in USA

Project in Japan

Project in Netherlands

JNBAN vacuum belt dryers have been included in the“ Eleventh Five-Year National Science and Technology Support Program, Zhejiang Science and Technology Department Major Science and Technology Public Relations Project and Zhejiang Province” Major Science and Technology Special (Priority Theme) Social Development Project. There are 4 papers and 6 patent applications accepted, including 4 invention patents, 2 special authorizations, and 10 practical patents. They won the third prize of Zhejiang Science and Technology Progress Award and the first set of products in Zhejiang Province.……

Wenzhou Jinbang Light Industry Machinery Co., Ltd. is a high-tech enterprise integrating R & D, manufacturing and sales. Professional in the production and sales of pharmaceutical, bioengineering machinery and equipment professional enterprises. The company mainly specializes in consulting, scheme design and manufacturing, budget, on-site installation and after-sale maintenance of traditional Chinese medicine extraction equipment, concentration equipment, separation and purification equipment, alcohol recovery equipment and drying equipment.……

Wenzhou Jinbang Light Ind Machinery Co., Ltd

E-mail: info@jnbantech.com

P.C: 325025

Address: No. 420 Binhai 23rd Road, Binhai Park, Economic & Technological Development Zone, Wenzhou, Zhejiang, China