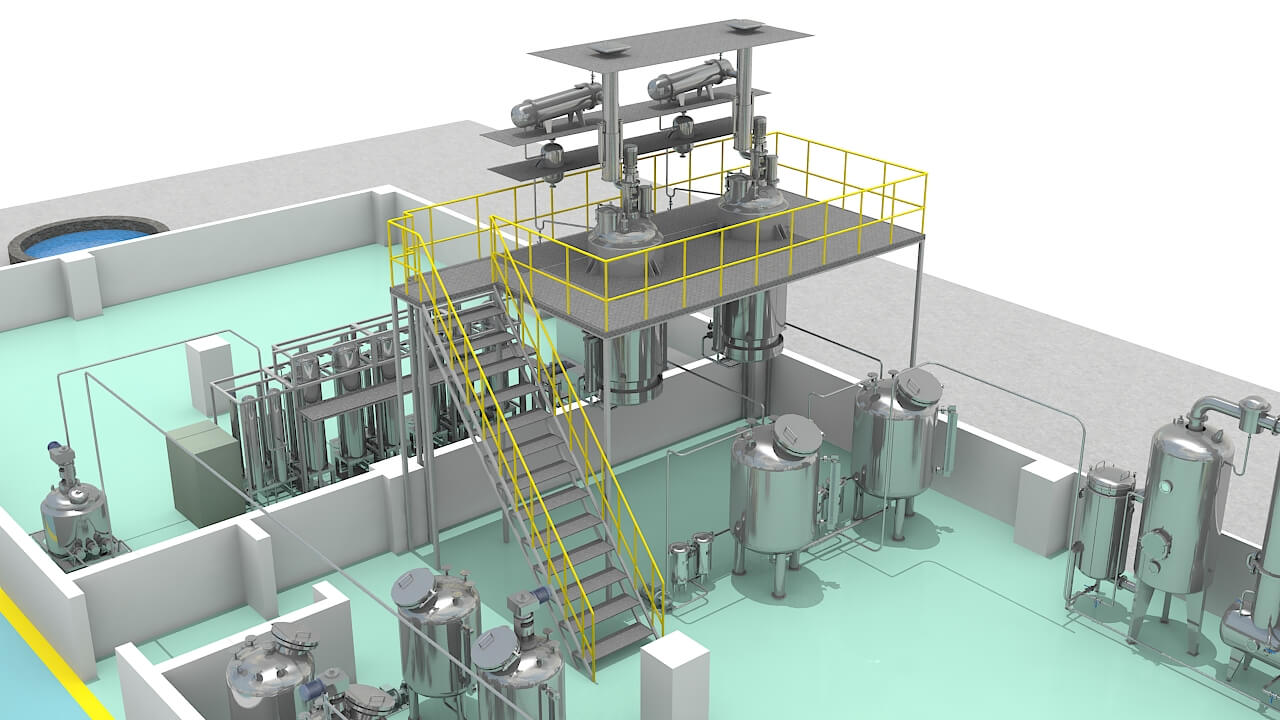

CBD processing equipment carries out oil extraction by employing a number of major steps.

The dynamic extraction tank can be used for atmospheric pressure, micro pressure, water decoction, warm imrnersion and cold immersion conditions in herbal&plant, food and chemical industries. The equipment is equipped with a stirring device to make the material extraction sufficient and increase the extraction rate

The produdt s mainly adapted to the concentrated producton processiof traditional herbal&plant health care products. natural seasonings food additves food. chemcal industry and other industries.H can prouide different proportons of extracts with different dryinig production miethods t has advantages of wide application range. easy operanion and low maintenance rate

It is applied to the freeze-precipitation of herbal&plant,oral liquid, food health products, etc, freezing or normal temperature precipitation of suspension,solid-liquid phase separation, and separation of wax and lipid substances.

Is the best thermal separation machine for heat-sensitive material because it is the gentlest type, causing the least amount of thermal degradation of product. It is a process of separation, purification and concentration of natural products, complex and thermally sensitive molecules. JNBAN molecular distillation units are wildly used for purification of oils, such as garlic oil, cod liver oil in chemical and pharmaceutical industries.The whole molecular distillation system includes supporting chillers, heaters, vacuum pumps and all accessories.

The materials are transported from the feed tank to the jacketed main evaporator. The main evaporator is continuously heated. The built-in scraper evenly scrapes the materials into a layer of flowing liquid film for instant evaporation. The light component materials begin to vaporize and adsorb on the built-in condensing coil, flow into the receiving bottle along the outer wall of the condensing pipe, and the heavy component materials flow into the receiving bottle along the inner wall of the main evaporator.

Industrial preparation liquid phase system is characterized by high efficiency, rapidity, high degree of automation,explosion-proof, etc. It is widely used in the separation and purification of pharmaceutical intermediates,biomedicine, synthetic drugs, natural products, fine chemicals, food additives and other fields. Industrial preparation of liquid phase systems can effectively improve production efficiency, improve automation, and improve product purity and yield.

The rectification column is a tower gas-liquid contact device for rectification. Using the characteristics of different volatility of each component in the mixture, the light component (low boiler) in the liquid phase is transferred to the gas phase, and the heavy component (high boiler) in the gas phase is transferred to the liquid phase, thereby achieving the purpose of separation. The equipment is widely used in solvent recovery in plant extraction, Chinese medicine, food, and chemical industries.

The belt dryer is suitable for continuous drying of raw materials,semi-finished products and finished products such as roots, stems and leaves. It can also be used for continuous drying of aquatic products and other agricultural and sideline products and crops. It is especially suitable for materials with high water content and high heat sensitivity.

JNBAN vacuum belt dryers have been included in the“ Eleventh Five-Year National Science and Technology Support Program, Zhejiang Science and Technology Department Major Science and Technology Public Relations Project and Zhejiang Province” Major Science and Technology Special (Priority Theme) Social Development Project. There are 4 papers and 6 patent applications accepted, including 4 invention patents, 2 special authorizations, and 10 practical patents. They won the third prize of Zhejiang Science and Technology Progress Award and the first set of products in Zhejiang Province.……

Wenzhou Jinbang Light Industry Machinery Co., Ltd. is a high-tech enterprise integrating R & D, manufacturing and sales. Professional in the production and sales of pharmaceutical, bioengineering machinery and equipment professional enterprises. The company mainly specializes in consulting, scheme design and manufacturing, budget, on-site installation and after-sale maintenance of traditional Chinese medicine extraction equipment, concentration equipment, separation and purification equipment, alcohol recovery equipment and drying equipment.……

Wenzhou Jinbang Light Ind Machinery Co., Ltd

E-mail: info@jnbantech.com

P.C: 325025

Address: No. 420 Binhai 23rd Road, Binhai Park, Economic & Technological Development Zone, Wenzhou, Zhejiang, China